Applications

- For short displacement routes

- transports heavy loads in mining,steel,machine,and bridge construction or as heavy roller conveyors

- particularly stable construction through contiuous cover plate

- can be bolted to the load

Key Features

- robust overall construction (frame construction)

- low overall height with high load capacity, identical in dimensions with AS+AM series

- firm connection, because the load or cover plate can be screwed

- most stable load absorption and distribution

- Model A-H (with hardened center plate) is used when the rollerskate is not moved under high load for a long time. As a result, a pressing of the hardened steel rolls is prevented in the standard non hardened center plate and ensures a uniformly low rolling resistance

- Model A-H-50CrV4 (roll material 50CrV4) is recommended if the risk of short term overload beyond the specified bearing capacity of the rollerskates can not be excluded or is probable

Operating Tips

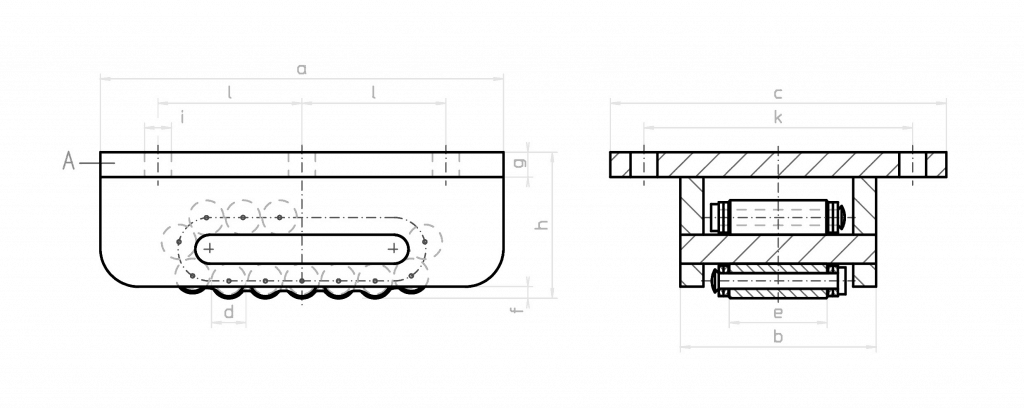

- Models I-IIIv have 4 fixing holes: the middle ones are omitted

- maximum displacement speed: ≤ 5m/min

- for uncontrollable load distribution problems (eg wind pressure) choose models with hardened center plates and higher quality 50CrV4 roll material

- Rolling resistance on models I-IIIv is 7-5% depending on the track conditions, 5-3% of the total load on the larger models

- also available with http://boerkey-gmbh.de/de/produktuebersicht/fuehrungsrollen/

- Location of the fixing holes can be arranged to suit customers requirements.

- Optional in galvanised or stainless steel construction

Models A, A-H

(H= hardened and machined center plate)

A-H-50CrV4

(roller material 50CrV4)

| Size | a | b | c | Ød | e | f | g | h | Øi | k | l | Supporting rolls | Roll number | Capacity max kN | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 210 | 100 | 175 | 18 | 51 | 6 | 13 | 76 | 14 | 140 | 75 | 5 | 15 | 150 | 8,9 |

| II | 220 | 113 | 190 | 24 | 60 | 10 | 14 | 87 | 14 | 155 | 75 | 4 | 13 | 200 | 11,7 |

| III | 270 | 130 | 210 | 30 | 68 | 10 | 14 | 104 | 18 | 175 | 95 | 4 | 13 | 400 | 19,3 |

| IIIV | 320 | 140 | 220 | 30 | 68 | 10 | 18 | 115 | 18 | 180 | 120 | 6 | 17 | 500 | 29,0 |

| IV | 380 | 168 | 270 | 42 | 76 | 19 | 19 | 145 | 22 | 220 | 140 | 4 | 13 | 650 | 51,0 |

| V | 530 | 182 | 300 | 50 | 86 | 19 | 19 | 165 | 22 | 240 | 205 | 6 | 17 | 850 | 92,0 |